03 Oct Ultrasonic Testing In NDT – Course Details And Syllabus

What is Ultrasonic Testing in NDT ?

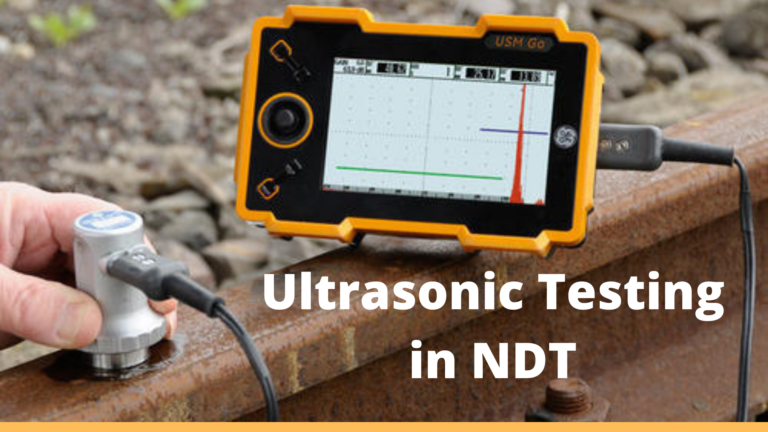

Ultrasonic testing also referred to as UT, is a type of non destructive testing. It is a volumetric ndt testing method which involves both surface inspection as well as inspection of flaws inside the sample. It identifies the internal structure of a material or sample by sending High-frequency sound waves using an ultrasonic transducer. The basic objective of UT is to detect defects, measure the parameters of it and analyse the hazardness and feasibility of operation of the specific tested material.

This testing can provide an insight on the size, thickness, orientation and nature of the detected defects. The sound waves used for the testing have much higher frequencies ranging from 500KHz to 20MHz which is very higher than the human hearing limit. UT is performed mainly on metals, steel and alloys but can also be performed on wood and composites, albeit with less resolution and concrete. Many industrial sectors like transportation sectors, construction, aerospace, metallurgy, automotive etc use this type of testing.

Materials used

Mainly the ultrasonic testing system consists of different functional units like a transducer, pulser/receiver and display systems.

Principle behind the Technique

HIgh frequency sound waves are used since they are very directional and will travel through the material (like steel or plastic ) till they are blocked by a boundary with a different medium (such as air). In that case the sound waves will reflect back to the source. These reflections are then analysed to identify the cracks or hidden flaws and to measure the thickness of the material.

In UT, a pulser/receiver is used to produce high voltage electrical pulses and the pulser drives the transducer to generate high frequency ultrasonic energy which is then passed through the material or sample in the form of sound waves. When ultrasonic testing is performed with an Electromagnetic Acoustic Transducer (EMAT), then there is no need of a couplant but in case of immersion testing there is a need of a couplant like oil or water.

Once the waves identify a change in the medium which means it reaches a discontinuity or the back wall of the material, a part of it will get reflected back to the source. This reflected wave is then transformed to electrical signal by using the transducer and is then displayed on the display system (screen). In the screen, the signal strength versus the time (from the signal generated to the time when echo was received) can also be represented. Since the signal travel time is directly related to the distance of the signal travelled, sometimes the information like the reflector location, orientation, size and many other features can also be found.

Basically there are two ways for receiving the ultrasound waveform.

They are reflection and attenuation:

- Reflection (Pulse-echo) mode: In this mode, the transducer plays the main role. So the transducer will send and receive the pulsed waves till the sound is reflected back to the source. The reflection can happen because of an interface like the back wall of the material or from a discontinuity within the object. The display system which is used for the diagnosis, displays the results in the form of a signal in the graph representing the intensity of the reflection versus the distance, which will give the representation of the arrival time of reflection.

- Attenuation (Through-transmission) mode: In this mode, a transmitter as well as a receiver is used. The transmitter will send the ultrasound through one of the surfaces and the receiver(separate) will detect the amount that has been received on the other surface after passing through the whole medium of the material. The difference in the amount of the sound transmitted will signify the discontinuities or any other imperfections between the transmitter and the receiver, thus making their presence visible .The loss of ultrasonic energy which can happen due to the separation of the surfaces can be reduced using a couplant.

Advantages and disadvantages of Ultrasonic Testing

Advantages:

- Non-hazardous to the inspectors or any nearby personnel as well as for the materials used

- Penetrating power is very high compared to other ndt methods so that it can be used to detect even deeper flaws in the material

- Type of Volumetric testing so that it can be used for defects on both surfaces and sub-surfaces

- Single side access is only required(Pulse-echo method)

- Highly sensitive, permitting to even small flaws detection

- High accuracy in determining the position, shape and thickness of the defects

- Instant results using the electronic equipment’s

- Portable and automated equipment’s

- Require only minimal preparation

Disadvantages:

- Required experienced technicians for the manual operations since more technical knowledge is required for the procedures

- Surface should be applicable to transmit ultrasound

- Defects with complex shapes and roughness are difficult to identify

- Couplants are required for attenuation method

- Defects which are linear parallel to the sound beam will be difficult to identify

- Required reference standards for efficient flaw characterisation and equipment calibration

Enroll for 1 month preparatory classes for ASNT level 2 and 3 Ultrasonic Testing Certification

Gamma NDT academy offers NDT preparatory classes for candidates who intend to appear for the ASNT Level 2 and 3 Ultrasonic Testing certification exam and also provides certification in QC course in Kerala.

We will cover all the syllabus under ASNT for Ultrasonic Testing and conduct mock tests to prepare you best for the certification exam. We will also share study materials and sample questions which you need to revise. We have a 100% success rate for NDT level 2 and 3 certification courses.

Gamma NDT academy training institute is located in Kerala, India. We provide online classes for candidates who cannot attend our training sessions in-person. Gamma NDT academy is well known for the NDT level 2 course and NDT level 3 course in India.

No Comments