24 Feb Laser Testing Methods in NDT – Holography, shearography & profilometer

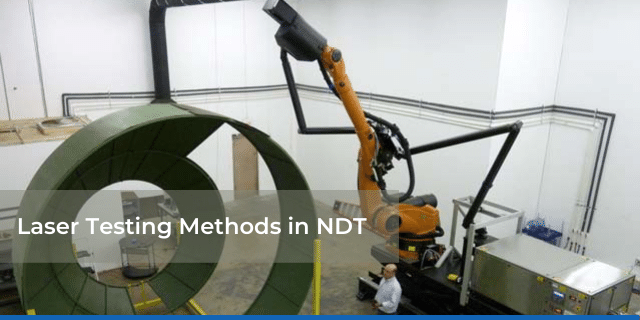

Lasers can be used to generate and measure ultrasonic waves in materials. Laser based NDT methods came to acceptance with an increase in the use of composite materials and sandwich structures in industries. These types of structures required high speed and large area inspection for subsurface defects like disbonds, delaminations, sheared core, invisible damage in aircraft, missiles and marine composites.

There are 3 main laser testing methods in NDT. Holography, shearography and profilometry testing all of which make use of lasers to conduct testing.

Holography laser testing method

Holography testing methods use high frequency vibration to identify irregular internal structure or disbonds. This non-destructive testing method is used for the real time inspection of complex components like aero engine turbine blades, felt metal engine seals, plasma coated artificial hip and knee joints.

Laser shearography testing method

This method utilises an interferometer to identify the out of plane derivative of deformation of the testing material due to the non homogenous strain field due to subsurface flaws. Out-of-plane stress is created by applying vacuum, vibration or thermal stress effects to the weakest bond of laminar structure. Shearography testing can identify changes in strains to 0.1 microstrain at video frame rates

Laser profilometer testing methods

Laser profilometer testing methods are largely preferred for cylindrical products. The major use is found in pipeline inspections for assessing highly corroded defects.

The principle behind the working of laser profilometry testing is based on image processing of laser beam when it is bent by the test object profile. Using the profilometer method crucial information regarding repair and operability can be assessed efficiently with an accuracy of 0.03mm and with a resolution of 0.05mm.

Benefits of laser testing methods in NDT

- Non-contact and remote testing is possible

- Can inspect equipment at extreme environments like high temperature.

- Adjustable and very small footprint

- Objects of small and complex geometries can be inspected

- Ability to detect very small flaws using high frequency beams

- scanning method for full coverage of inspection samples

Enroll for 1 month preparatory classes for Laser Testing Certification

Gamma NDT academy offers NDT preparatory classes for candidates who intend to appear for the ASNT Level 2 and 3 Laser testing exam.

We will cover all the syllabus under ASNT for Laser Testing and conduct mock tests to prepare you for the exam. We will also share study materials and sample questions which you need to revise. We have a 100% success rate for NDT certification courses.

Gamma NDT academy training institute is located in Kerala, India. We provide online classes for candidates who cannot attend our training sessions in-person.

Sorry, the comment form is closed at this time.